Your basket is currently empty!

Want to know how to get the best out of your construction fencing? Then you have to store and transport it properly! Read on to find out how today…

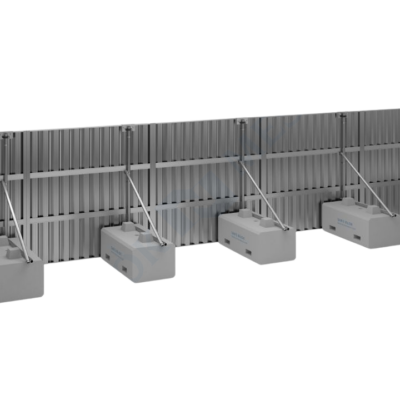

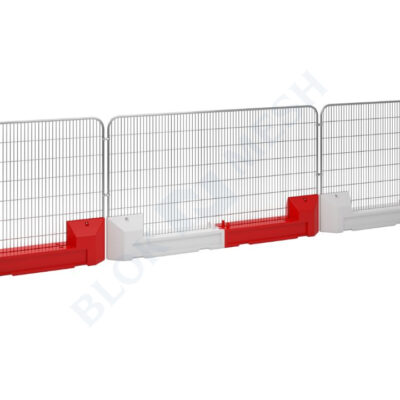

The easy, simple, and effective solution for keeping sites secure and unauthorised people out – temp fencing can do it all.

But whether you know it as temporary fencing or construction fencing, storing and transporting it properly can vastly increase its lifespan.

So, how can you safely store and transport temporary fencing?

Why does it matter how you handle temp fencing?

We understand that construction sites can be busy places, with short turnarounds and even tighter deadlines – but with proper care, each panel could last 5-10 years.

This comes from its increased durability, harsh weather protection, and anti-rust and corrosion properties.

However, incorrect handling can result in damage, breakages, and the scrapping of otherwise perfectly usable temporary fence panels.

So, how can you make sure you look after your temporary fencing properly?

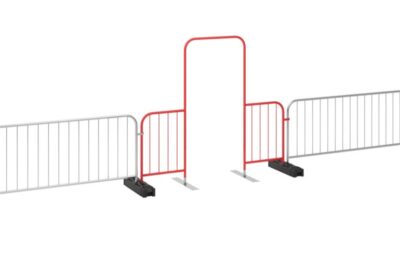

Removing portable fence accessories

Though it can be tempting if you are in a hurry or the weather has turned for the worst, it’s important to remove any and all accessories and attachments, including:

- Fence connectors

- Privacy screens

- Acoustic wraps

- Signage

- Gate panels

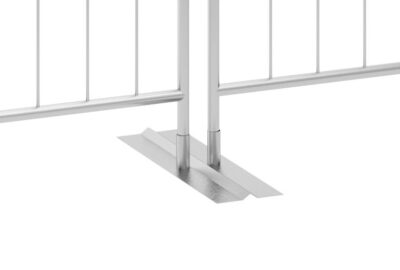

- Fence feet

Leaving these on can lead to further obstructions, making it harder to move and store each panel, and increasing the likelihood of accidental damage.

Transporting portable fence products with care

Probably a bigger culprit, the transportation of temp fencing can be far and above the most damaging factor of all.

This is because of the increased risk from:

- Carrying, loading, and unloading, especially if a forklift is used to move multiple panels at once

- Movement in the back of vans or lorries

As such, securing the fencing during loading and unloading – as well as when it is on the road – can limit the chances of potential damage.

Storing construction fencing properly

While it is weatherproof and strong, temp fencing needs to be stored properly to stop accidental damage during storage.

Most companies will choose to stack their panels, either horizontally on the floor or on a pallet, or vertically, between built structures or other equipment.

If kept under cover and physical contact with the elements is kept to a minimum, you will find that accidental damage is minimised and each temporary fence panel can last for longer.

Our top tips for keeping your temporary fence panels in good condition

If you are looking to keep your current stock of temp fence panels in the best condition for as long as possible, there are many things you can do – all of which are simple, easy, and don’t take a lot of time.

- Consider using manual movement options

If this isn’t an option, take greater care with forklifts and consider wrapping the forks themselves in foam sheathes to limit damage potential.

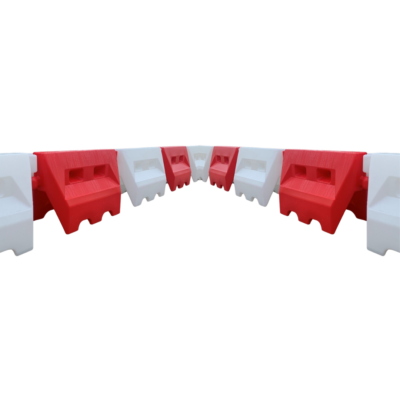

- Stack panels vertically if possible

This will help you optimise space and maintain stability.

- Strap or secure panels when not in use

Strapping prevents portable fence panels from shifting or toppling over.

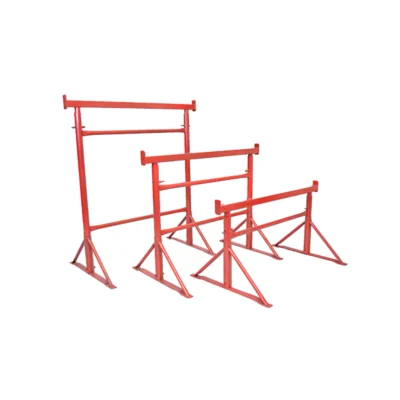

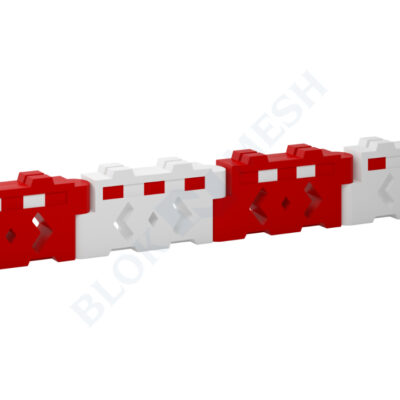

- Consider investing in transport racks or stillages

These structures are designed to hold construction fencing steadily in place, be it in transport or during storage.

It can also remove the issue of forklift damage – as the forklift can support the fencing from the rack or stillage.

- Store accessories and attachments separately

Whether you use baskets, boxes, or stacks on pallets, storing everything individually allows your staff to move panels without damage and quickly access what they need for each job.

Ask the construction fencing experts at Blok ‘N’ Mesh

While implementing these changes can mean interrupting and rewriting well-ingrained routines, the money you save on replacement temporary fencing makes it a very worthwhile cause.

Plus, the sooner changes are implemented, the sooner you will see results.

To find out more about our collection of temporary fencing, including gates, feet, and accessories, why not browse our extensive range or give us a call on 01226 654 040. As market-leading manufacturers, we can help customers across the UK and in Europe.